HOW TO PULL WHEEL BEARING HUBS – THE RIGHT WAY

FORD, SUBARU, COMBO & RAIL KITS

NEW - SAVE BIG ON ANY PROKIT PLUS KIT (PROP) WITH TOMMY RAIL

Tommy® pulls the most stubborn wheel bearing hubs, without having to remove the control arm or use a hammer. This wheel bearing hub removal tool is for Select Ford and Subaru Models. Also available in a Ford/Subaru Combination kit.

Consider pairing your Tommy Wheel Bearing Puller ProKit with the Tommy Rail: This accessory works with our Tommy Wheel Bearing Hub Extractor and allows technicians to apply even more force to the wheel hub to make any wheel bearing removal quick and easy.

LITHIUM EXTREME PRESSURE ANTI-WEAR GREASE

TOMMY PULLER RAIL ACCESSORY

NEW - SAVE $100 ON ANY TOMMY PROKIT PLUS KIT (PROP) WITH TOMMY RAIL

This kit works with our TOMMY PROKIT PLUS KITTommy Wheel Bearing Puller and allows technicians to apply even more force to the wheel hub. Make any wheel bearing removal quick and easy on select Ford and Subaru Models with ProMAXX tooling.

TOMMY EXTREME GREASE APPLICATOR

Tommy Pistol Action 6,000 Psi Extreme Pressure Grease Gun is a lever action grease gun dedicated for applying Tommy Lithium Extreme Pressure Grease. Compatible with ProMAXX Tool’s 14oz grease tubes.

NEW AT PROMAXX

-

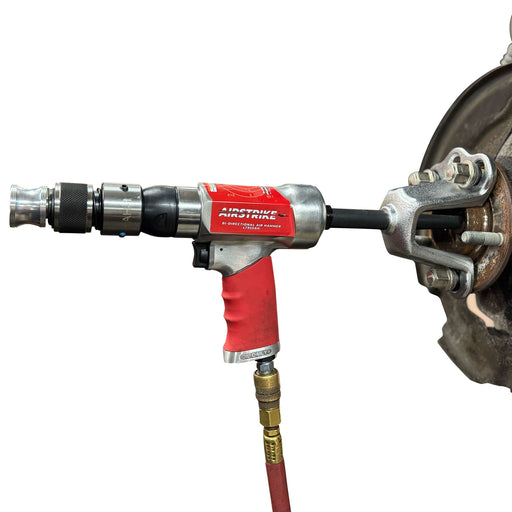

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment