SHOULD I REUSE MY EXHAUST MANIFOLD?

There are many reasons somebody may opt for a new exhaust manifold on their vehicle. Usually, it’s to increase exhaust flow and hence increase their engine performance with an aftermarket manifold. Other times, it’s after the OEM manifold has caused mounting bolts to break. With the latter, you might consider whether to replace it with a brand-new manifold.

Here are a few points to consider when making that decision:

1. WHAT ARE THE DIFFERENCES BETWEEN OEM AND AFTERMARKET EXHAUST MANIFOLDS?

OEM Exhaust Manifolds

OEM exhaust manifolds are manufactured with cost in mind and to meet a broad spectrum of users’ performance needs in mind. They are not built to deliver the highest level of horsepower and unfortunately are prone to cracking, warping and therefore broken manifold bolts. Most OEM exhaust manifolds are formed from the factory using fine grain cast iron, and like most metals, it expands and contracts during duty cycles of heating and cooling.

Pros:

- Low Cost

- Readily available

Cons:

- Do not deliver peak vehicle performance capabilities

- Made of unseasoned cast metal, leaving them prone to warping

Aftermarket Exhaust Manifolds

These aftermarket options can come in cast, ceramic coated, stainless or longer-in-length headers. So what are the positives and negatives of using an aftermarket exhaust manifold?

Pros:

- Can increase horsepower & improve performance

- May increase the engine noise (could be a pro or con…)

Cons:

- Can be an expensive

- May disrupt the performance of your vehicle if not calibrated correctly

- Requires alterations to the exhaust system

2. WHY DO WARPING AND BREAKAGE OCCUR WITH EXHAUST MANIFOLDS?

You might be asking yourself, “Why do exhaust manifold bolts break?”. Well this happens naturally, and at first, the manifold and mounting studs are in a state of “elastic deformation.” Elastic deformation is the expansion and contraction over a period of time where it retains the size and shape. Each duty cycle causes tension stress on the bolts that hold the manifold in place. The mounting hardware exhibits flexibility over time but as the manifold continues to expand and contract more dimensionally. Each consecutive time creates larger and larger tension forces that move beyond the elastic state of deformation and become what is referred to as “plastic deformation.” Essentially, the manifold stretches beyond the point of return and fractures the mounting stud, leaving the manifold permanently deformed and dimensionally changed. This expansion and stretching of the manifold bolts over numerous duty cycles eventually cause too much tension which stretches them beyond capacity and causes them to fail.

3. SHOULD I REPLACE MY EXHAUST MANIFOLD?

The most productive solution is always driven by the application. If you are seeking a boost in power and efficiency, aftermarket exhaust solutions (headers) mentioned earlier in this article might be the answer. If you are simply contemplating an exhaust manifold bolt repair, your dealer/service center can replace it with a new factory OEM replacement manifold.

We highly recommend OEM replacement manifolds that can be procured from your authorized dealer. Aftermarket replacement cast iron manifolds are available and at first glance may appear more economical. However, depending on your application (trailer towing, loading, snow plowing, heavy usage and frequent duty cycles) will accelerate the need to replace them within your ownership timeline. If that occurs, it will quickly erase any economic advantage you would expect, making your best option to be to buy OEM right from the start. When you choose an OEM manifold, you, your dealer, or service center, can rely on exact fitment and emissions output.

Lastly, there is another option that this is economically comparable to offshore replacement manifolds and will actually outperform a replacement. Your dealer/service center may offer a service to have your old manifolds resurfaced rather than purchasing new. This can be preferable because the cast iron has already been seasoned (expanding & contracting through cycles). This option will restore your vehicle's stock performance characteristics, meet local emissions standards, as well as provide the benefit of a significantly longer-lasting repair than the aftermarket/offshore option.

In addition, we recommend replacing all of the bolts with OEM mounting bolts or studs. When you replace the manifold with a new one, it will be prone to the same warping that broke the bolt originally – so at the very least, be sure to replace all of the bolts with OEM mounting bolts or studs

ProMAXX Tool is the industry leader in exhaust manifold repair. If you're stumped by a difficult repair, need expert insight or tooling, call ProMAXX for free, unlimited technical support: (724) 941-0941

Check out ProMAXX Tool’s premium exhaust manifold repair kits for Ford, GM, CDJR, and more.

NEW AT PROMAX

-

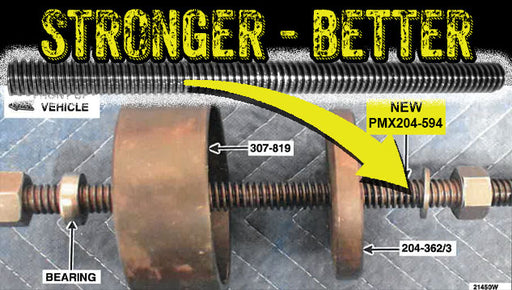

Forcing Screw Alternative to Ford 2020-2022 Explorer Recall Special Service Tool part# 204-594 "Thunderbolt"

Part#: PMX204-594Original price $0.00 - Original price $0.00Original price $0.00$149.95$149.95 - $149.95Current price $149.95Original price $0.00 - Original price $0.00Original price $0.00$149.95$149.95 - $149.95Current price $149.95 -

SAVE: 25%

Ford Power Stroke 6.7L Fuel Injector Copper Compression Seal Puller and Seal Saver ProKit

Part#: PMXISPS200BSEOriginal price $199.95Original price $29.95 - Original price $199.95Original price $199.95$29.95 - $149.95$29.95 - $149.95Current price $29.95Fuel Injector Seal Puller/Saver ProKit Part #: PMXISPS200PRO Introducing the cutting-edge Ford Power Stroke 6.7L Fuel Injector Copper Compression S...

VIEW MOREOriginal price $199.95Original price $29.95 - Original price $199.95Original price $199.95$29.95 - $149.95$29.95 - $149.95Current price $29.95SAVE: 25% -

Ford 6.7L Power Stroke Diesel EGR Tube Broken Bolt Repair Kit - Nino

Part#: PMXN200PROOriginal price $499.95 - Original price $749.95Original price$499.95 - $749.95$499.95 - $749.95Current price $499.95Nino EGR Tube ProKit Part #: PMXN200PRO 6.7L Ford Power Stroke Diesel Exhaust Gas Recirculation EGR Repair Kit - Nino The ProMAXX® EGR (Nino™) repa...

VIEW MOREOriginal price $499.95 - Original price $749.95Original price$499.95 - $749.95$499.95 - $749.95Current price $499.95 -

Ford 6.7L Diesel Power Stroke Fuel Injector Broken Bolt Repair Kit - Nico

Part#: PMXO200PROOriginal price $549.95 - Original price $699.95Original price $549.95$549.95 - $699.95$549.95 - $699.95Current price $549.95Now, Take $100 Off Nico ProKit PlusAnd…Get an Extra Insert - That’s a $179 Value! Ford 6.7L Power Stroke Diesel Hold-Down Bolt Repair ProKit Plus #...

VIEW MOREOriginal price $549.95 - Original price $699.95Original price $549.95$549.95 - $699.95$549.95 - $699.95Current price $549.95 -

Ford 6.7L Power Stroke Fuel Injector Puller With Air-Hammer Assisted Punch / Slide Hammer Options – PowerPull 200

Part#: PMXPWP200PROPOriginal price $149.95 - Original price $389.95Original price$149.95 - $389.95$149.95 - $389.95Current price $149.95Revolutionize fuel injector removal with the ProMAXX PowerPull Ford 6.7L Power Stroke Fuel Injector Puller Kit. It is the only puller that does not...

VIEW MOREOriginal price $149.95 - Original price $389.95Original price$149.95 - $389.95$149.95 - $389.95Current price $149.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.