WHY DO DRILL BITS BREAK?

Having the right drill bit in the right application can make the toughest job a breeze. Here are a few reasons your drill bits might be breaking. From the experts, here are recommendations for your drill jobs to prevent broken bits.

DRILL BIT MANUFACTURINGA standard drill bit can be manufactured in many ways, but most commonly and economically is stamped or crimped to form the twist or flute. The point and cutting edges are then ground for the correct size and application. That method is where accuracy is not as important as just getting a hole in the material.

On the other hand, machine-grade tools are made for precision applications, where accuracy and repeatability are most important. Machine-grade tooling is turned, ground flat, and incorporates features that deliver the precision and accuracy required for the application.

Machine-grade tools are made from high-quality metals like cobalt or carbide. Micro-points are added so the tooling stays on track. Cutting edges are ground at complex geometries demanded by the hardest of materials, including titanium, boron, extra-strength, and case-hardened steels, most of which are encountered in exhaust manifold bolt repairs.

DRILLING CONDITIONSWe recommend applying a small amount of drilling and tapping fluid to any heavy-duty drilling job. This will reduce the amount of torque and resistance your bit meets when drilling the initial pilot hole.

Another staple in any one of our drill applications are drill bushings. Drill bushings mounted to an alignment fixture can be the difference between success and a costly failure. Threaded mounting bushings are most common in machine shops because of their superior accuracy.

DRILL BIT DESIGNA threaded mounting bushing incorporates a proprietary and precision machined edge that mates to an opposite edge in the tool which overrides the threads to bring the assembly into perfect alignment with the cylinder head. Threaded mounting bushings will assure perfect alignment and perpendicularity of tooling. How the tooling system is used will determine repair times and quality.

Not all drill bit designs are made equally. Using a bit with the right flute volume will allow the buildup of chips to be expelled as you move your drill in and out of the drill hole.

Using machine-grade tooling and following the above steps will ensure productive and efficient repairs that will boost productivity and keep your customers’ cars safe and running at peak performance.

Be sure to check out our ProDrill series of bits, bushings and taps - all precision engineered to cut through the hardest materials with speed and accuracy.

NEW AT PROMAXX

-

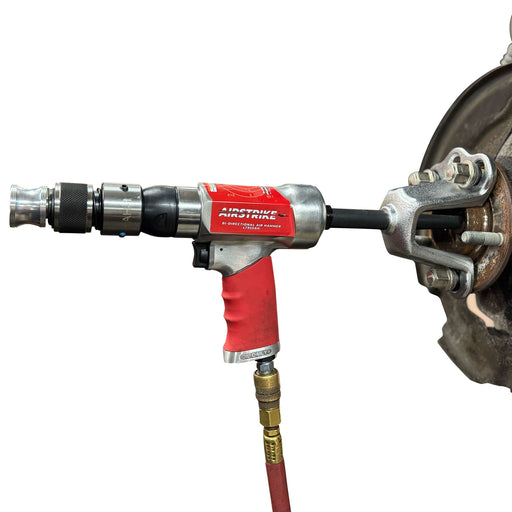

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95 -

Crankshaft Repair Kit Ford Coyote & EcoBoost - Harmonic Balancer Bolt. Avoid Engine Teardown

Part#: PMXCSR035KIT - ECOOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Ford 3.5 Ecoboost Harmonic Balancer Bolt Puller Kit: PMXCSR035KIT - ECO• Compatible with Ford 3.5L Bolt Part: HL3Z-6A340-A & F5RZ-6A340-B• May ...

VIEW MOREOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment