WHY DID YOUR BOLT EXTRACTOR BREAK?

Broken bolts happen – whether we like it or not. Whether working on commercial vehicles or maintaining a fleet vehicle, moisture, corrosion, heat and heavy loads can put major stress on bolts under the hood. When technicians are faced with this predicament there are a few options at their disposable. They can weld on a nut, drill down the stud and tap the threads, or drill a pilot hole and use an extractor.

Tapping the thread is a great option but does require some confidence, skill and patience to accomplish the job. The other two options require the technician to leverage the existing threads to guide the remainder of the bolt out of the hole. What many technicians do not realize as they begin to turn an easy-out is that the state of the threads is what caused the bolt to break off in the first place – which unfortunately leads to an extractor broken off inside an already comprised bolt hole.

So what’s wrong with the threads?

Bolts experience multiple environmental factors, all of which can lead to breakage. A notorious reason for breakage is the tremendous amount of heat bolts are exposed to, especially those on an exhaust manifold, adjacent to a turbo. When these bolts are heated to such high temperatures then exposed to cool water or moisture from the road or condensation, they can break under the slightest bit of tension. When these bolts break, it’s because they are actually stretched, thus elongating the threads. This environment often leads to a partial thread being left behind in the softer aluminum of the head.

How do you fix compromised threads?

Owner and President of ProMAXX Tool, Jeff Del Rossa, recommends the ProCutter; a tool that consists of a cutting edge and an arbor and attaches to a ¼” drill chuck.

“I’ve seen bolts broken off due to almost every factor you can think of,” said Del Rossa. “The worst thing a technician can do is go in and try to turn out a bolt-on threads that were the reason for the break in the first place. You’ve got to go in and clean the debris, corrosion and partial thread that is left behind. The ProCutter is the only product on the market that does that.”

The ProCutter is designed to prepare the surface and threads that technicians will use to turn out the broken bolt. Its blade and arbor design work to remove the partial thread left behind left from broken bolts. It will flatten the broken stud, giving a drill bit an even cutting surface and preventing the drill from walking and drilling off-center. The ProCutter will also remove burrs which can expose the remaining bolt to additional torque as it’s turned out – all in just five seconds.

Technicians are under the gun to get trucks out of the service bay and back to work. Service leaders and General Managers are looking for more ways to become more productive. ProMAXX Tool's ProCutter is one more example of our mission to provide technicians with tools and knowledge that make them more productive.

BROKEN EXTRACTOR.EXTRACTOR

NEW AT PROMAXX

-

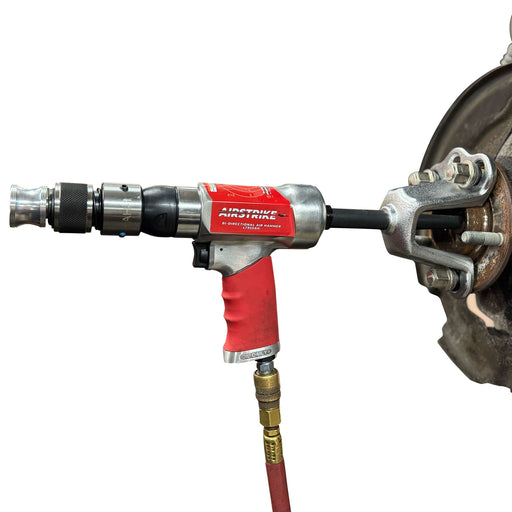

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor® and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95Original price $249.95 - Original price $629.95Original price$249.95 - $629.95$249.95 - $629.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment