WHY ARE FORD ECOBOOST EXHAUST MANIFOLD BOLT STUDS BREAKING?

The 3.5L Ford EcoBoost engine has grown in popularity for the past decade. Models of the Ford F-150, the top-selling truck in the United States for four decades, have been using the 3.5L EcoBoost since 2011 to provide power and improved fuel economy. In 2015, the Ford Transit van adopted the small but mighty motor.

The key to providing the power of a 6.0L in an engine almost half the size is a high fuel pressure system and twin-turbo, which can pull in 25 percent more air than a naturally aspirated engine. The engine head is also made of aluminum, which provides additional energy savings with lower weight and better heat dissipation, which aluminum provides compared to cast iron heads.

What happens when you put this tiny monster under load though?The twin turbos spin up to 170,000 rpm, producing high torque. This creates an intense source of heat, nestled directly adjacent to the exhaust manifold, which is belting out extremely hot gas due to the high-pressure fuel system feeding into the other side of the system.

After running under load on a regular basis, the cast metals under the hood have been exposed to extreme heating and cooling cycles. In the case of the Transit, problems can compound. Heat dissipation is reduced because of a more compact engine bay. Combine this with the Ford Transit usually carrying a payload, and heat can lead to increased issues.

1. Metals such as steel can lose strength after being exposed to high temperatures like those created by the exhaust system and the turbochargers on the 3.5L EcoBoost.

2. Dissimilar metals such as a titanium exhaust manifold bolt and the softer aluminum head do not work well together, especially when exposed to extreme heat, cold or road debris like salt. A chemical reaction takes place which essentially welds the two components together.

Combine these two risks, and the situation can become extremely difficult when a gasket is being replaced and the titanium bolts on the exhaust manifold break due to their loss of strength and inability to back out of the threads in the aluminum head.

WHAT IS THE BEST METHOD TO REMOVE BROKEN ECOBOOST EXHAUST MANIFOLD BOLTS?

If you’re unlucky enough to have this happen – here is what you MUST keep in mind.Exposure to extreme heat is the last thing you want for these metals. This will only continue to harden the stud, especially titanium; forget using a torch to loosen the bolt. In many broken bolt cases, welding a nut to a stud and backing it out is a perfectly fine solution. However, this method won’t work if the stud is essentially welded to the aluminum head. Backing out a stud with a welded nut will only result in plenty of broken welds, frustration and hours lost in productivity.

The experts at ProMAXX Tool have worked on hundreds of broken bolts in this situation on the 3.5L EcoBoost and the only guaranteed method for removing broken bolts is drilling out the broken stud with the highest quality and hardest tooling at your disposal. We prescribe our Ford-approved Elizabeth II ProKit for the 3.5L Ford EcoBoost This kit includes a drill template and sequential drill bushings which allow technicians of almost any skill level to confidently drill on center every time. The kit also includes ProMAXX Platinum Tooling which is tough enough to cut right through the heat-hardened titanium exhaust manifold bolt. After the broken bolt has been drilled, a ProMAXX extractor (ProTractor) can be hammered into the pilot hole in the stud and backed out.

If the risk of breaking an extractor is a concern that your shop doesn’t have time to deal with, the kit can be upgraded to be “extractorless!”The extractorless upgrade adds sequential drilling steps, allowing the technician to drill the bolt completely out, then chase the threads with a tap and restore the aluminum EcoBoost engine head back to factory-new condition.

Our objective is to provide productive solutions for complicated repairs. The 3.5L Ford EcoBoost’s design offers power yet accompanies some risk when (not if) a broken stud does occur in the aluminum head. There are plenty of tricks for backing out broken bolts, but with this repair, the most productive solution is to use the method that works consistently every time. Learn more about the Elizabeth II ProKit for the 3.5L EcoBoost by visiting the section on our website or by calling ProMAXX Tool at (724) 941-0941.

EXHAUST MANIFOLD BOLT

INTAKE MANIFOLD BOLT

IGNITION COIL HOLD BOLT

TURBO MOUNT BOLT REPAIR

NEW AT PROMAXX

-

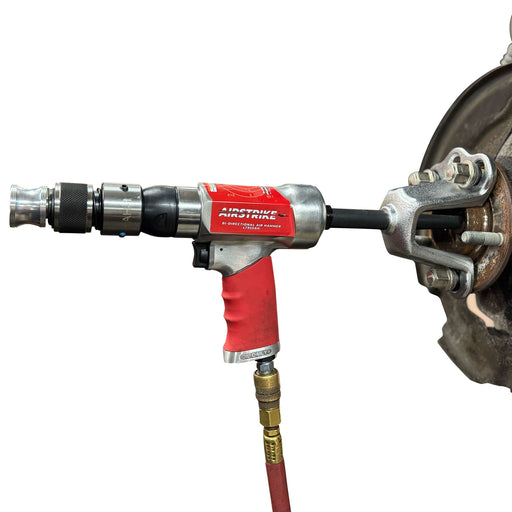

Wheel Bearing Hub Puller - Air Hammer Powered

Part#: PMXTOM475PROOriginal price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95Original price $69.95 - Original price $499.95Original price$69.95 - $499.95$69.95 - $499.95Current price $69.95 -

Hold-A-Rotor and Secure Disc Brake Rotors in Place on 12mm & 14mm Studded Hubs - STC71000

Part#: STC71000Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99Original price $19.99 - Original price $19.99Original price$19.99$19.99 - $19.99Current price $19.99 -

Ford 6.7L PowerStroke, GM 6.6L Duramax Fuel Injector Fuel Line Puller Adapter Combo Kit – Powered by Air Hammer

Part#: PMXPWP955PROOriginal price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95Original price $89.95 - Original price $699.95Original price$89.95 - $699.95$89.95 - $699.95Current price $89.95 -

Volvo 2.0L Drive-E, VEA Exhaust Manifold Bolt Repair USA Made for XC40 XC60 XC90 & More: ProKit W/Additional Accessories - Victoria

Part#: PMXV200PROOriginal price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95Original price $349.95 - Original price $349.95Original price$349.95$349.95 - $349.95Current price $349.95 -

Fuel Injector Pullers quickly remove stuck EcoBoost injectors without engine teardown save 15 hrs Air-Powered for Ford 1.0L/1.5L/3.5L/3.7L engines

Part#: PMXPWP915AOriginal price $249.95 - Original price $329.95Original price$249.95 - $329.95$249.95 - $329.95Current price $249.95Original price $249.95 - Original price $329.95Original price$249.95 - $329.95$249.95 - $329.95Current price $249.95

SHIPPING INFO

For Saturday delivery or special shipping instructions, please contact ProMAXX Tool M-F 8 a.m. – 5 p.m. EST at 724-941-0941. Expedited Orders Placed by 1pm EST will be Processed Same Day | UPS Ground Processing Time is 1-3 Business Days

WARRANTY INFO

Offering a range of policies

NEED HELP

Contact our support team today

724-941-0941

Promaxx Tool Address

1121 Boyce Road

Suite #2000

Pittsburgh, PA 15241

Any motor company logo on this site is a Registered Trademark. ProMAXX Tool is not affiliated with any of the motor companies on this site.

Leave a comment